-

Porsche 911 silencers

One of the most persistent problems faced by any enthusiastic 911 owner who wishes

to compete in their car is noise. Whatever variant they decide to use, the rear engine

layout always determines that because of the extreme packaging constraints and the

proximity of other noisy components the sound level measured from the exhaust

tailpipe exceeds that of other sportscars. Add to this the desire that most competing

drivers have to try and improve the performance of their car by increasing power

and/or reducing weight and you have an idea of the scale of the difficulties faced by

an exhaust designer.

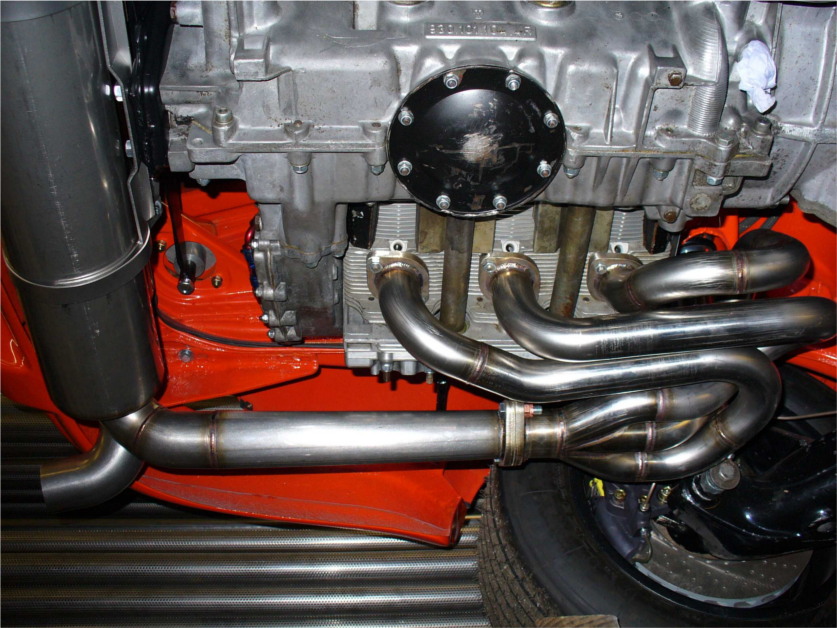

Early cars:

All 911’s up to the introduction of the 993 have essentially the same limited amount

of space available for silencers. This led the original designers to come up with the

banana shaped silencer that fits between the rear of the engine and the rear

bumper.

The impact bumper cars introduced around 1974 still used this as the main silencing

element, with the addition of a small pre silencer alongside the engine. If a fibreglass

replica of the rear bumper is used as per the 911SCRS race and rally cars, there is a

bit more space available behind the engine for larger silencers. At the time the SCRS

was competing noise was not really an issue and the most efficient design of twin

tapered megaphones that ran straight from the end of each 3 into 1 manifold to exit

just clear of the bumper were only nominally muffled with tiny oval cans. Today if

this independent configuration is desired for maximum power, it is necessary to fit

twin transverse round silencers on top of each other, with the left hand bank of

cylinders exiting through a tailpipe on the right and side and vice versa. Linking both

cylinder banks together via a 2 into 1 pipe can be desirable for torque on smaller

capacity engined rally cars, but the complicated routing required of this pipe

inevitably will compromise the space left for a silencer, which is why the two

functions were combined within the OE silencer. The standard OE silencer remains a

good compromise between power and noise, but its single tailpipe design will

compromise the power of the highest output engines that can now be fitted to these

early body cars. Pattern copies of this silencer exist but should be avoided because

they often feature power sapping internal baffling arrangements that cannot be seen

from outside and often are not as efficient at attenuating the unique flat six noise

frequencies.

The 964 body affords a little more scope for more silencing with a combination of

simpler shapes of oval and round boxes, but inevitably the power output potential,

pipe sizes and hence noise volume increases in line with the arrival of 3.4 and 3.6 litre

engines so the same challenges largely apply.

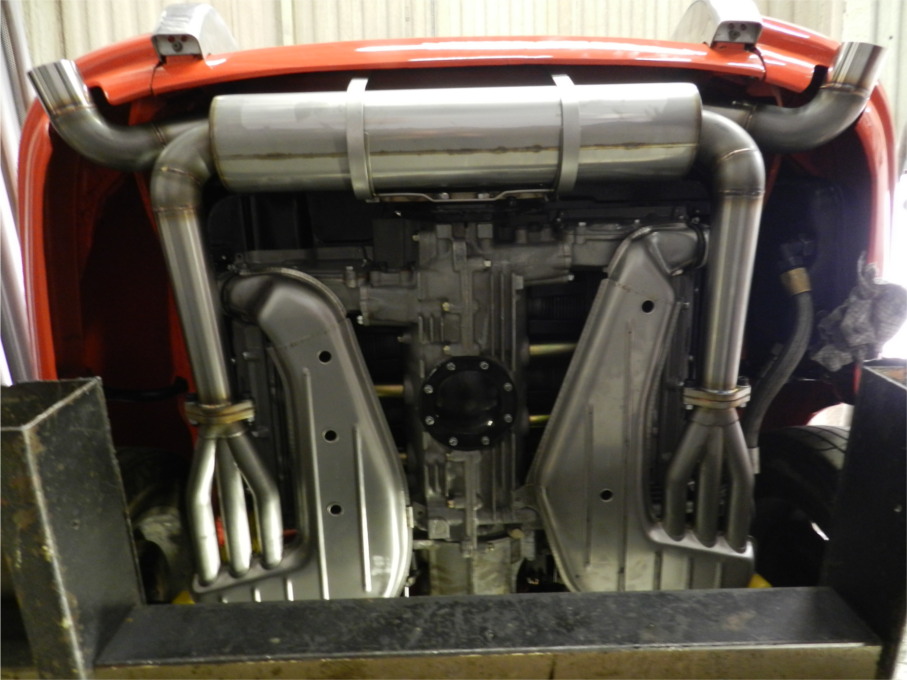

993:

The more emphatically rounded rear end styling of this model freed up considerably

more space in the rear arches just behind the rear wheels, which allows fitment of

symmetrical oval reverse flow silencers each side. Although road noise levels

dictated the use of somewhat restrictive internals to the OE system, at last the scope

exists for a free flowing system to be designed that uses the extra volume, and pipe

length available to give a useful increase in power without producing an unacceptable

increase in tailpipe

noise.

If this power is to be regularly exploited in competition or trackday, it is

recommended that the silencers are only made from the highest grade stainless steels

and preferably are of a repackable design to enable the noise attenuating material

within the silencer to be replaced without the cost of replacing the entire system. This

is because of the higher exhaust gas temperatures resulting from the more extreme

ignition timing and leaner fuel mixtures made possible by

much more precise electronic engine control systems. Initially when the 993 was

raced in the UK they ran with the boot lid/spoiler propped open, which meant that the

noise from the air-cooled engine (and amplified by the fan) was directed in the same

direction as the tailpipes, i.e. straight at the scrutineers noise meter. However, when

the RS biplane spoilers were fitted the engine noise was directed upwards away from

the exhausts, which meant that the efficient straight through systems were still viable.

996:

The 996 and onwards are fully water-cooled of course, which means and end to the

noisy engine mounted fan, and more sound absorbing water channels in the engine

castings. 996’s also have yet more room behind the rear bodywork for mounting

silencers, which means that even fire-breathing race-tuned GT3RSR’s can be fitted

with enough silencers to comply with trackdays, without compromising their

awesome performance. For racing the emphasis is on ultimate performance and as

such the smallest silencers are fitted that only just comply with circuit noise limits, so

as to minimise the weight slung out behind the rear axle.

Silencing secrets:

The essential element to a performance system is the straight-through or absorption

type of silencer. This consists of a perforated duct surrounded by sound absorbing

material, which converts sound energy (vibration) into heat. This type of silencer

typically attenuates the high frequency noises from the engine leaving the

characteristic low bassy burble to emanate from the tailpipe. There are two problems

with this type of silencer when fitted to 911’s, firstly with the earlier smaller bodied

cars it is difficult to fit a silencer that contains enough volume of sound deadening

around a big enough perforated tube within the confines of the bodywork. Secondly,

the short pipe run on any rear engined car between the engine and silencers, doesn’t

allow for much dissipation of heat before the gasses encounter the duct. This can lead

to rapid deterioration of the sound deadening fibres which are then sucked into the

exhaust stream and blown out of the tailpipe. One of the tricks to reducing the noise

further is to combine the two cylinder banks, to allow a degree of noise cancellation to

take place. This is where the peak pressure wave from one cylinder is cancelled by its

opposing wave form being present in the same section of silencer. A mild version of

this can be effected by having a carefully positioned crossover or balance tube

between the two independent pipe runs from each cylinder bank. This minimises the

possibility of reversion waves being reflected into the cylinder head during valve

overlap, which can have a detrimental effect on the incoming fuel air charge and

efficient cylinder filling. If more sound reduction is necessary both cylinder bank

exhaust flows can be arranged to directly face each other, preferably within a damped

chamber in the silencer. Turbocharged cars tend to produce lots of low frequency

noise, because the high frequencies are lost in the exhaust turbine, and they need

much larger ducts to cope with the hotter gas flows. However, they don’t suffer as

much from reflected waves as the incoming charge is pressurised above atmospheric

pressure, and the turbine interrupts the reversion pulses anyway. The lower

frequencies can only be attenuated in large well damped expansion chambers unless

restrictive baffling is used which will sap power by increasing back pressure in the

system preventing effective spool-up of the turbo.

Copyright Joe Ellis 18 December 2005

Follow BTB Exhausts on @BTBExhausts and LinkedIn or Subscribe to our newsletter.

Read more about our Motorsport Exhaust Systems or Download our Brochure.

- T +44 (0) 1327 261797

- E sales@btbexhausts.co.uk