-

Noise

BTB Exhausts Ltd have been making competition exhausts for 30 years, and that experience when

coupled with cutting edge sound analysis software enables them to silence extremely loud race cars

whilst minimising any loss of performance. BTB’s Managing Director Joe Ellis has compiled this

article to help competitors understand some of the issue they face in silencing their cars effectively.

So why are racing cars loud? It is true that silencers can reduce performance if they interfere

with the tuning of the exhaust system. An efficient exhaust system allows the engine to get rid of the

waste gases as quickly as possible. So any part of the exhaust that increases the pressure in the

exhaust pipe above atmospheric pressure will force the engine to work harder to pump those gases

out. This is called back pressure. The other way the exhaust helps the engine produce power is by

careful management of the standing pressure waves that are set up in the manifold tubes by the

pulsing energy created by the valves opening and closing. This effect is more difficult to understand,

but can be significantly affected by the design of the silencer. Race engine designers would much

rather not have to deal with silencers, as they don’t want anything to interfere with their optimum

power solution. Race car designers don’t want to add weight to their cars if they don’t have to. All

circuit owners are under pressure to reduce noise, so what is the compromise that must be struck

between them and you, the competitors?

You can use an off the shelf silencer, in a “one size fits all” type of solution. This isn’t always effective

because not all the car/engine combinations have the same characteristics, so, what might work well

on one car may not work on another. This applies not only to the noise reduction but also its effect

on performance. Large capacity engines with relatively conservative cam timing and little valve

overlap need high gas flow rates, but aren’t too affected by reflective wave forms. Conversely small

high revving engines, can cope with smaller exhausts, but with their relatively higher state of tune

are much more sensitive to reversion waves upsetting the carefully managed pulse tuning in the

manifolds. The effectiveness of a silencer on a particular type of car is also determined by what type

of noise monitoring is in place. If the noise is established by a static noise test it can create different

sound frequencies compared to when the car’s noise is tested as it drives by a microphone at the

side of the track. It can be hard to find an acceptable compromise between performance and noise,

but it is rarely impossible. Here are some tips that you may use to reduce noise successfully without

it reducing power.

Noise is energy and one of the fundamental principles of physics is that you cannot make energy

disappear. What you can do is change its form. Sound energy can be dissipated by converting it into

heat. The traditional absorption silencer (or glass-pack) is very effective at reducing high frequencies

by using this principle. Absorption silencers generally work best at attenuating high frequencies, and

are therefore ideally suited to small capacity high revving engines. This is why they tend to produce a

deeper sounding exhaust note. However, they only work if the packing used in silencers is not

packed in so tight that the sound waves are merely reflected back.

Tip one:- Don’t pack too tight. The reason people do this is because their packing

disappears during the course of a race and the exhaust gets too loud. The correct answer is to use

material of the right density that will withstand both the vibration and the heat created by their

particular engine. Suitable materials now exist that will withstand temperatures of over to 900degC.

It is important to make sure they are used in a form that stays inside the silencer.

A density of packing material of around 150grammes/litre of silencer volume works well in most

cases. Packing material usually consists of glass based fibres. BTB use and recommend Accoustafil,

which is a woven blanket made from a single extruded filament of either E-glass or S-glass. The S-

glass is a texturised silica filament and withstands temperatures of up to 1000degC. For silencers

that are positioned close to the engine, or are subject to extreme exhaust gas temperatures, a layer

of stainless steel wire wool or gauze mesh next to the perforated tube can provide additional

thermal protection to the sound absorbing media. Another factor worth considering is the distance

the sound waves travel through the packing, so the Outside diameter of the can needs to be

proportional to the size of the perforated pipe passing through it. A greater range of frequencies will

be attenuated if the perforated tube is not concentric to the outer skin, therefore offset inlet and/or

outlet positions, or an oval shaped silencer may give better results than a simple cylindrical can.

Similarly the material chosen for the outer skin should be carefully considered, as reflected waves

can add to the incoming sound or drumming caused by thin metal can radiate sound externally.

Carbon fibre is a suitably acoustically inert skin material, but has yet to be proven in high

temperature applications.

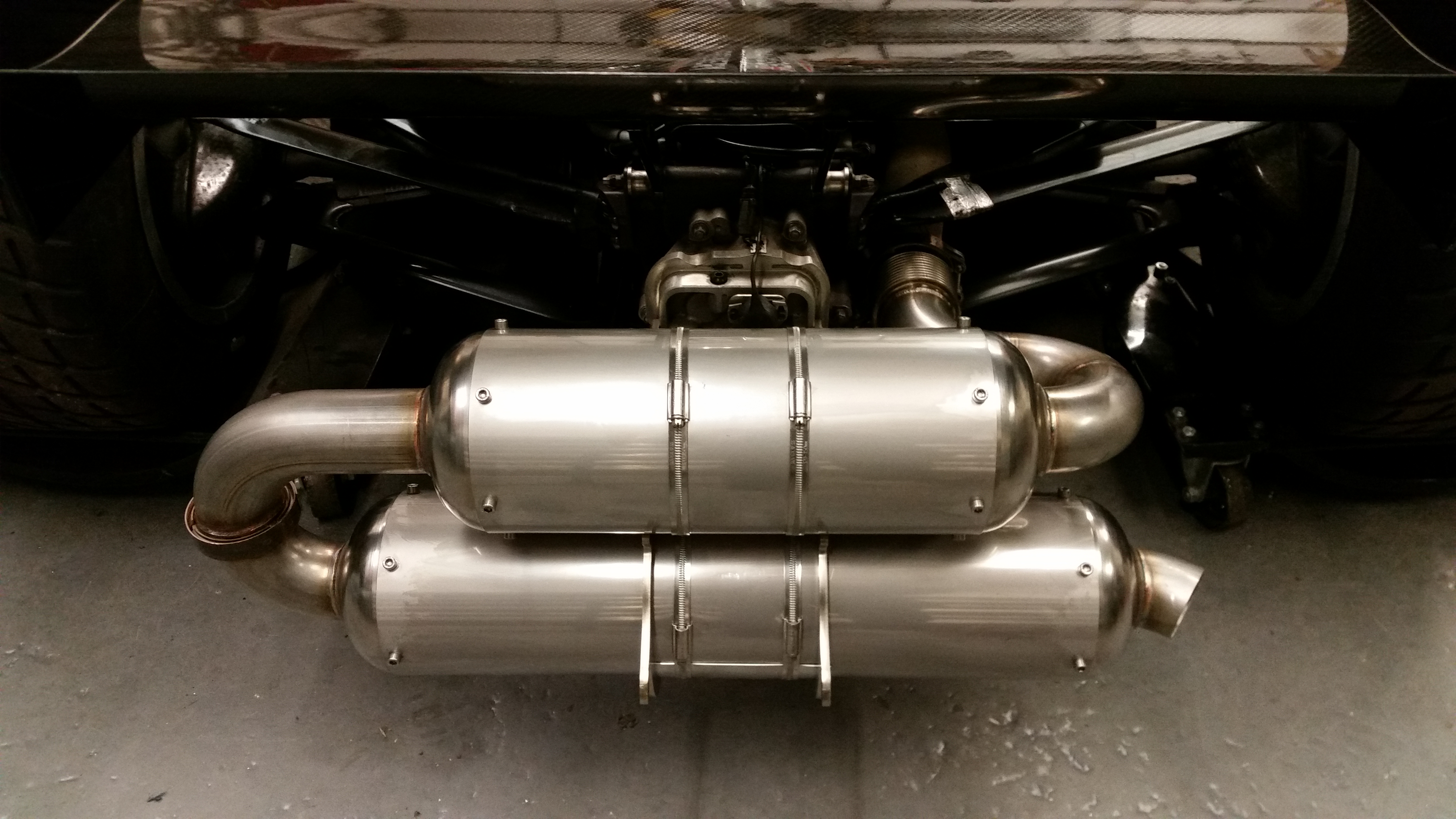

So what about bigger capacity engines? Volume is the key here. These silencers need sufficient flow

rates to cope with much more gas being passed through them. If you think about the fundamentals,

these larger engines with less extreme cam timing are less sensitive to reflective waves. Therefore

chambers can be used to create opposite wave forms to cancel out the incoming noise. The rule of

thumb here is that the bigger the engine the bigger the volume of resonating chamber that you will

need to attenuate the incoming frequency. Sometimes these chambers don’t even need to see

direct flow from the engine, but can be branched off to the side, either as a simple quarter wave

tube, or a Helmholtz resonator. These can be particularly successful for cars that produce a specific

frequency of sound, and can be easily tuned to allow cars to pass a static test where conditions can

be repeated accurately. This will also apply to turbocharged engines, as the turbo cuts down the high

frequency noise very well on its own, but the resulting low pitched sound has to be attenuated by a

large expansion chamber.

Another tip for multi cylinder engines to is to use their own sound to cancel itself out, by,

for example linking the cylinder banks of V engines together. The firing pulses that arrive at the

merge point out of phase will tend to cancel each other out.

After the noise has left the silencer we must not forget the influence of the tailpipe. Any length of

plain pipe will tend to amplify the sound entering it, and especially so if, like a trumpet, the diameter

increases. Many people, often in desperation will try and point the tailpipe to the ground, or in any

direction they can that will point away from the measuring instrument. In my experience this has

little or no effect. What does seem to work, particularly with high frequency noise, is to keep the

outlet pipe from the silencer as short as possible. It will help if you can continue some sort of noise

absorption within the tailpipe itself by using a perforated liner. Equally important to static

measurements is to keep the tailpipe is as far away as possible from other noise sources, such as air

intakes, cooling fans, superchargers etc.

Follow BTB Exhausts on @BTBExhausts and LinkedIn or Subscribe to our newsletter.

Read more about our Engineering and Prototype Services or Download our Brochure.

- T +44 (0) 1327 261797

- E sales@btbexhausts.co.uk